Our products

New motors

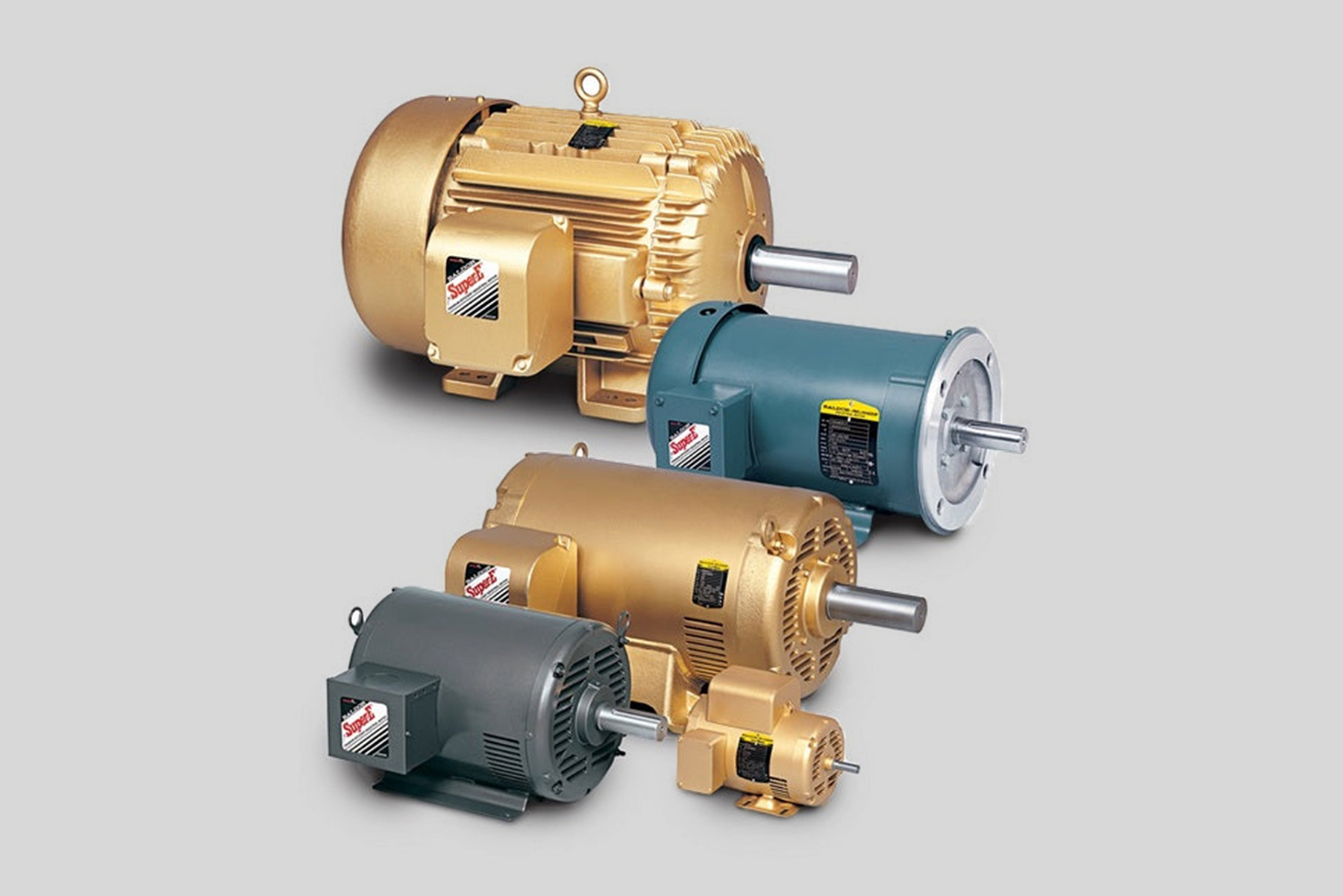

3 Phase Low Voltage Nema Motors

Designed for B.C.’s commercial, light and heavy industries, our extensive three-phase motor inventory includes:

- Open Drip Proof (ODP)

- Totally Enclosed Fan Cooled (TEFC)

- Severe Duty IEEE-841

- Explosion Proof

3 Phase MV & HV Above Nema Motors

Compact and powerful, these motors are ideal for precision-driven applications:

- 2,000 to 14,000 volts

- Enclosures include: Open drip proof (ODP); Weather protected type 1 and 2 (WPI, WPII); totally enclosed air to air cooled (TEAAC) and more

- Squirrel cage and wound rotor designs

Custom modified Motors

We modify and produce custom or specialty motors in as little as three days.

New Motors

3 Phase Low Voltage Nema Motors

Our high-efficiency, three-phase, low-voltage NEMA motors deliver exceptional performance and durability for commercial, light and heavy industrial markets in British Columbia and beyond.

These compact, yet powerful, motors are ideal for precision applications: automation systems, robotics, conveyors and small machinery. They’re designed to meet demanding performance standards, ensuring consistent torque, low heat generation and energy efficiency.

Our motors are available in premium efficiency ratings and at various speeds: 3600, 1800, 1200 and 900 RPM.

They’re suitable for sine wave, inverter duty and vector duty applications and constructed from cast iron, rolled or stainless steel and aluminum.

We also provide options for rigid bases, C-faced and D-flanged mounting configurations.

New Motors

3 Phase Low Voltage Nema Motors

Our high-efficiency, three-phase, low-voltage NEMA motors deliver exceptional performance and durability for commercial, light and heavy industrial markets in British Columbia and beyond.

These compact, yet powerful, motors are ideal for precision applications: automation systems, robotics, conveyors and small machinery. They’re designed to meet demanding performance standards, ensuring consistent torque, low heat generation and energy efficiency.

Open Drip Proof (ODP)

ODP enclosures are designed for motors in relatively clean and dry environments.

Their natural cooling capabilities allow air to circulate freely to facilitate the natural cooling of motor components.

They’re ideal for applications where motors aren’t directly exposed to liquids.

Totally Enclosed Fan Cooled (TEFC)

TEFCs are best-equipped to handle environments where dirt, dust and moisture are present. That’s because their motors are enclosed and include an external fan to blow air over the motor for cooling.

TEFCs provide an ideal balance across performance, energy consumption and heat management.

Our motors are available in premium efficiency ratings and at various speeds: 3600, 1800, 1200 and 900 RPM.

They’re suitable for sine wave, inverter duty and vector duty applications and constructed from cast iron, rolled or stainless steel and aluminum.

We also provide options for rigid bases, C-faced and D-flanged mounting configurations.

Severe Duty IEEE-841

The hallmarks of the IEEE 841 motor include improved reliability, efficiency and performance of severe duty motors, effectively helping to prolong the life of the motors and decrease unwanted and costly downtime.

Motor sizes across manufacturers are standardized, allowing for easy interchangeability when sourcing brands.

Explosion Proof

Explosion-proof enclosures are designed for hazardous locations where explosive gases or dust may be present.

These enclosures are capable of containing an internal explosion without rupturing.

They’re rated for different groups and divisions of hazardous locations and built to heavy-duty construction specs to withstand internal explosions.

New Motors

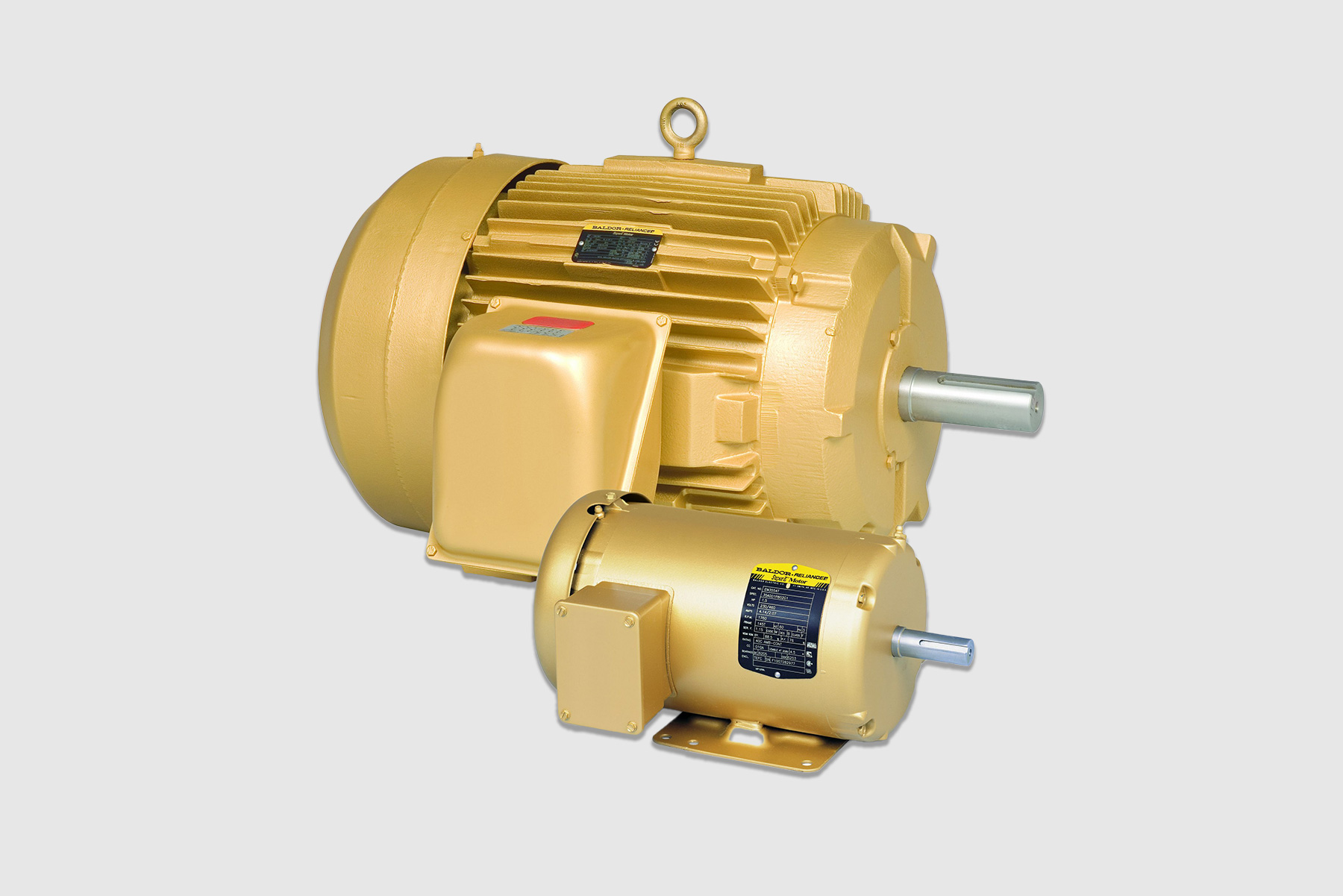

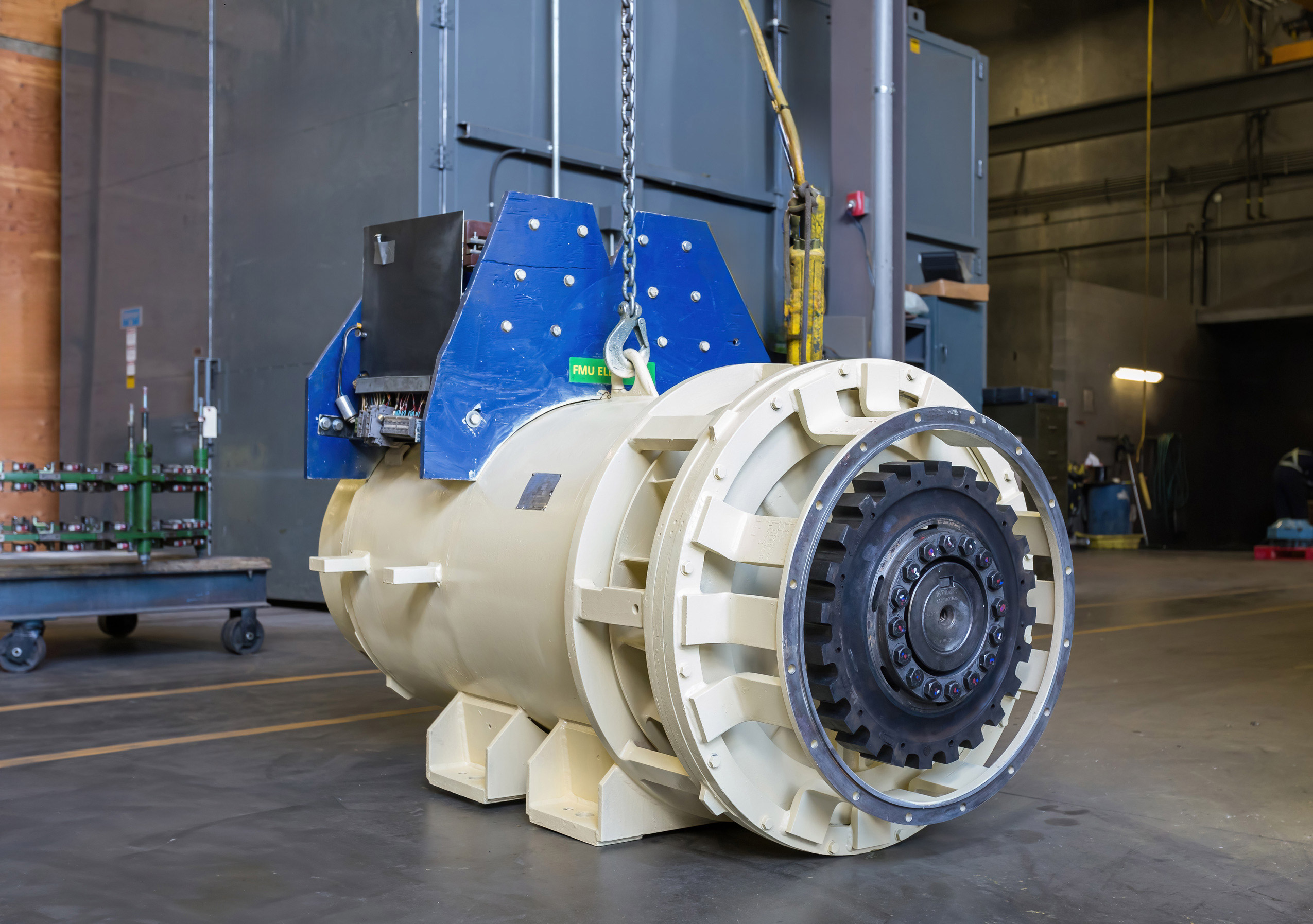

3 Phase MV & HV Above NEMA Motors

Armature Electric offers a full suite of motors suitable for heavy-duty industrial applications, including compressors, conveyors and pumps.

These motors are available in different sizes and power ratings to meet the diverse needs of B.C.’s industries. With deep technical expertise and access to high-quality components, we deliver customized motor systems that guarantee optimal efficiency, durability and exceptional integration into complex operations.

Our team collaborates seamlessly with clients to develop customized motor configurations that precisely address their specific needs for torque, speed, voltage and environmental conditions.

These motors are designed to meet global standards and are compatible with international systems that are suitable for industries requiring robust performance under continuous or variable loads.

Engineered for superior efficiency, reliability and extended operational life, our motors excel in demanding environments.

New Motors

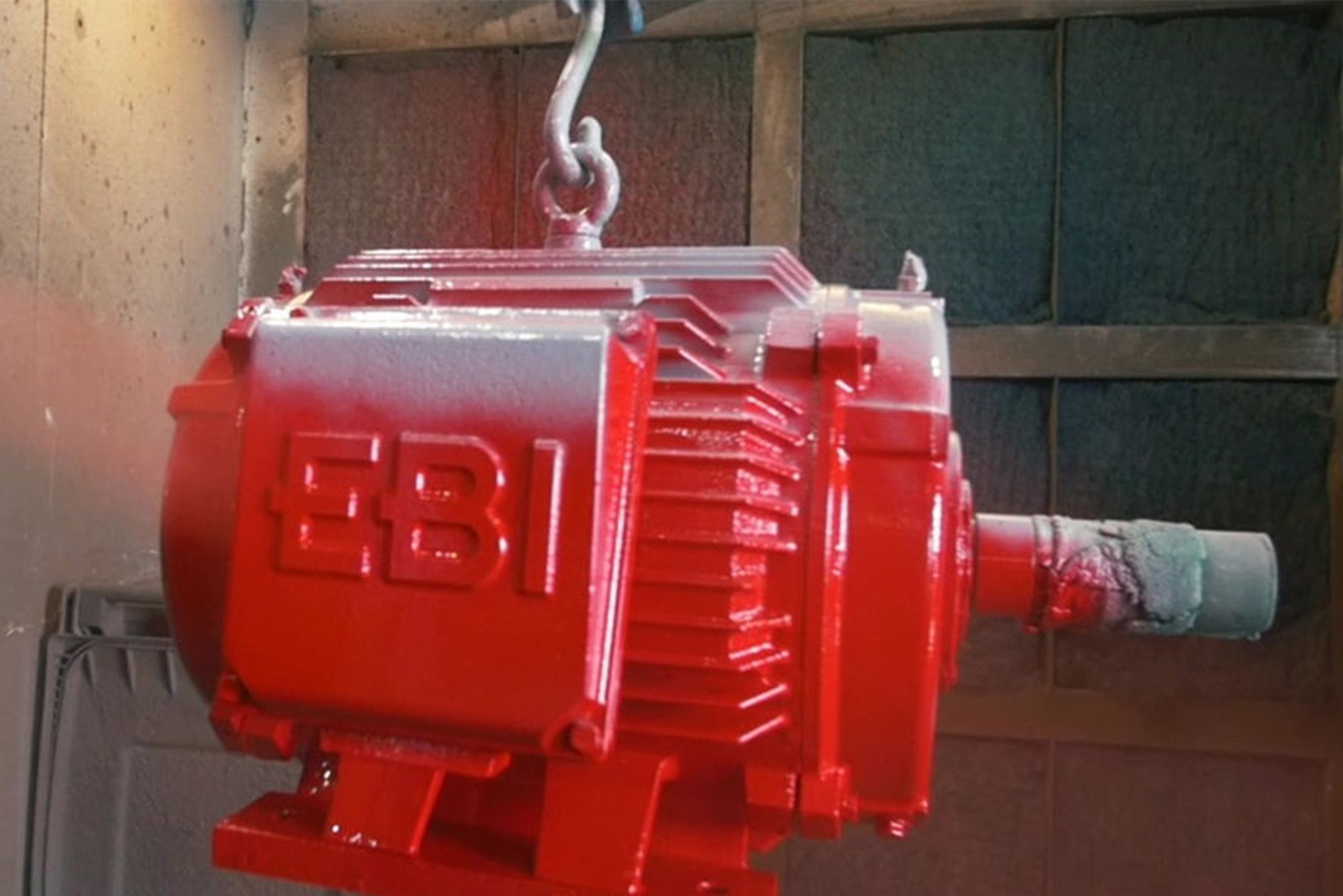

Custom Modified Motors

Armature Electric specializes in engineering and producing custom or specialty motors in Vancouver, with lead times as short as three working days.

We offer high-temperature motors.

“Kiln Duty” Motors

These motors are built to withstand some of the most challenging conditions found in wood-drying kilns: extreme humidity, high heat and corrosion.

The motors are built with materials that can tolerate high temperatures and are often coated with corrosion-resistant materials.

“Cooling Tower” Motors

Cooling tower motors are typically found in the HVAC; chemical, oil and gas and power generation sectors.

Derived from one of the toughest platforms and used in the most demanding applications, they provide a high level of performance inside a cooling tower’s hot and humid environment.

View Our Other Products

We proudly partner with industry leaders with proven track records of international success.

Armature partners with industry leaders like ABB-Baldor, Weg Motors and US Motors/Nidec to provide Low voltage NEMA Motors and 3 Phase MV & HV Above NEMA Motors.

Our shop and marine expertise, along with technical field services, are available 24/7/365.

We ensure industries operate with dependable solutions and responsive service.