Shop Services

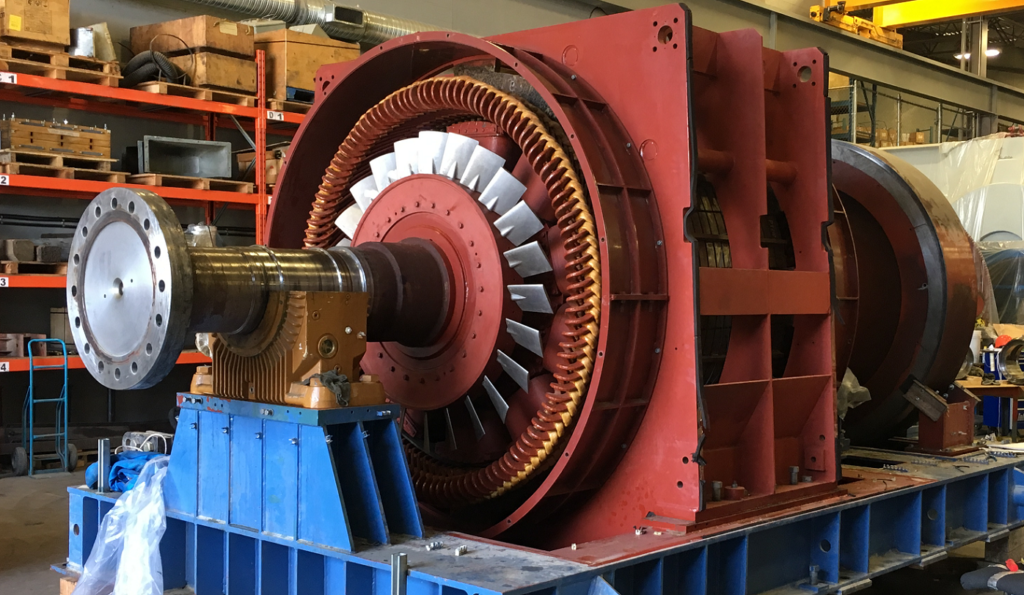

Our facilities at Armature Electric Ltd are second to none. Built in 2012, our state of the art 32,000 sq. ft. Service Center with up to 40 ton lift capability can accommodate the largest of electro mechanical equipment. (Motors, Generators, Transformers, Magnets, Pumps, Specialty Coils)

Our team of knowledgeable and experienced sales and service staff work with you every step of the way to ensure your equipment is repaired, replaced or serviced as quickly and skillfully as possible.

Our shop services include:

Overhaul Services

Wash and oven dry components

Bearing changes

Modifications

Specialty coatings

Rewinding Services

AC Stators through to 30,000HP and up to 13.8KV

Wound Rotor Motors

DC Field Coils

Armatures

Synchronous Rotor Poles

Rotor Re-barring

Specialty Coils

Magnets

Stator and rotor Lamination Re-stacking / replacement

Core loss testing

Machining Services

Journal rebuilding

Shaft manufacture

Shaft modification

Shaft straightening

Milling

Housing re-sleeve

Welding Services

Metal Spraying

MIG welding

TIG welding

ARC welding

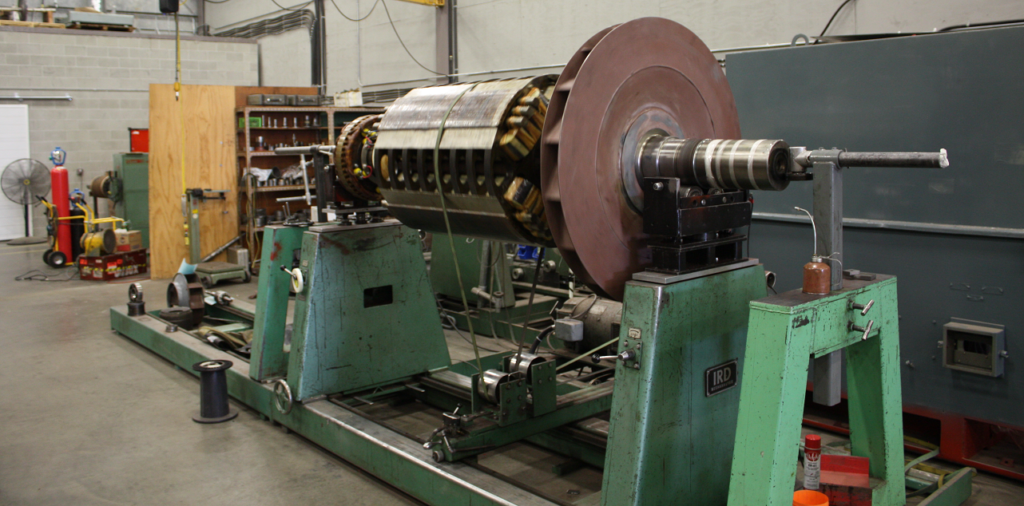

Dynamic Balancing

Up to 25,000 lbs., using Easy Balance instrument and software

Our shop equipment includes

- 40 ton lifting capability (2 X 20ton, South Bay)

- 10 ton lifting capability (2 X 5 ton, North bay)

- 150 ton press

- Large Bake Oven 16’ x 12’ x 12’

- Small Bake Oven 7’ x 7’ x 10’

- Temperature Controlled Burnout Oven with digital data logging 8’x8’x7’

- Large steam cleaning bay

- Large Varnish Dip Tank with Elantas Water based resin (Environmentally friendly)

- 4 Lathes

- Milling Machines

- Specialty Welding and Fabrication Bay

- 5,000 lb. Balance stand

- 15,000 lb. Balance stand

- 25,000 lb. Balance Stand

- Easy Balance Computerized Balancing software

- Phenix Core Loss Tester

- Motor Test Center 60-4160 VAC, 0-750 VDC 300 Amps

- Electrom ITIG II Winding Analyzer & Baker D12R Winding Analyzer

- Custom Rotor and magnet Winding Table

- 50KV DC Hi-POT

- 5KV Megger and P.I. tester

- PdMa-Predictive Motor Analysis

- Infrared thermography analysis